Ship-in-a-bottle catalysts

By: David Bradley

Porous minerals, such as

zeolites, existed in nature for

millions of years before chemists spotted their potential. They have now used

them to sieve out compounds one from another, catalyse reactions, single out

other molecules in sensors and make soap powder work more effectively by mopping

up dissolved metal ions. There are, however, a limited number of these

off-the-shelf minerals in nature so chemists have spent the last few years

looking for ways to tailor their own versions for specific separating, catalytic

and sensors.

Porous minerals, such as

zeolites, existed in nature for

millions of years before chemists spotted their potential. They have now used

them to sieve out compounds one from another, catalyse reactions, single out

other molecules in sensors and make soap powder work more effectively by mopping

up dissolved metal ions. There are, however, a limited number of these

off-the-shelf minerals in nature so chemists have spent the last few years

looking for ways to tailor their own versions for specific separating, catalytic

and sensors.

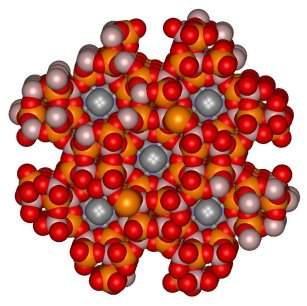

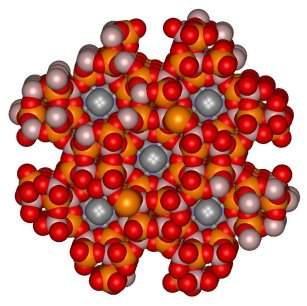

One approach they have tried is to use small

organic molecules as templates around which a porous mineral structure can be

built. This has proved very successful leading to a whole host of new synthetic

minerals with cryptic names such as the ALPOs, the ZSMs and the UCSBs. Many of

these have useful chemical properties but have not quite achieved the degree of

fine-tuning for particular applications that St Andrews chemist Paul Wright

believes they can. Wright and his team are working on designer

templates which can exert far more control over the ultimate shape and size of

the pores formed in a synthetic zeolite. In 1997, they had found that an easy to

prepare linear diquinuclidinium ion, which is positively charged, flexible and

carries bulky end groups, could be used to template the synthesis of a new

series of porous minerals. They dubbed these new minerals STAs (for St Andrews)

and STA-1 and STA-2 were the first created by heating inorganic aqueous gels

containing the template molecules at 150-200 Celsius. They then took the concept of these tuneable

diquinuclidinium templates to the more shapely triquaternary alkylammonium ions

to create a magnesioaluminophosphate with much larger pores, which they called

STA-5. When the templates are removed these minerals can act as shape selective

catalysts for small molecules. STA-2, for instance, can handle molecules up to 4

� in size, while STA-5 has pores 7� in diameter that give access to much

larger internal cavities.

The critical point, according to Wright, is

that the rational design of the template allowed them to create materials

analogous to the natural zeolites and whose internal pore geometry closely

matches the shape of the included templates. It should therefore be possible to

design structures that are suitable for shape selectivity towards desired

products in chemical reactions such as hydrocarbon conversions and

functionalisation. STA-2, for example, converts methanol with high selectivity

to olefins able to escape from the small pores, which is a potential route to

producing feedstock ethylene and propylene.

Spurred on by their successes, Wright's team

set about designing other templates to make minerals with different pore shapes

and sizes that might have other novel catalytic and sieving properties.

Wright points out that until now the shape and

size of the pores is often dominated by the organic template and this is

certainly the case with the latest template to be exploited by his team. The

researchers have used a macrocyclic molecule,

1,4,8,11-tetramethyl-1,4,8,11-tetraazatetradecane, to create a synthetic

magnesioaluminophosphate mineral STA-6. The pores, explains Wright, have

'remarkably high symmetry and form a very close fit around the azamacrocycle.'

The template molecule itself also possesses functionality - inorganic chemists

have long studied their properties in cation complexation and catalysis.

The crystals of STA-6 formed during synthesis

are microscopic and require a scanning electron microscope to see their

tetragonal prismatic shape. However, crystal size does not matter in this

instance as the structure of STA-6 was readily determined by synchrotron X-ray

diffraction.

When the researchers blasted the mineral at 550

Celsius in a stream of oxygen they could remove all traces of the organic

template. The hollowed out mineral is all that is left behind with its

tetrahedrally connected framework and its large symmetrical pores intact The

result is a catalytic solid, but points out Wright, it might be better to leave

it in and use its functionality for cation exchange and catalysis.

While many synthetic minerals have their own

catalytic abilities, Wright's team is also collaborating with St Andrews' David

Cole-Hamilton to incorporate or trap transition metal complexes within the pores

of their minerals. This means that catalysts that normally have to be dissolved

with the starting materials to produce a homogeneous system can be kept in a

separate phase but remain just as active as the reagents react within the pores

of the mineral. This is known as the 'ship-in-a-bottle' method and was

originally developed by N Herron of Dupont (Wilmington, DE) and later by Thomas

Bein at Purdue University in West Lafayette, Indiana. The catalyst is made

within the pores of the mineral and cannot escape during use because it is too

large or the wrong shape. The mineral with its catalyst payload can simply be

filtered off from the product once the reaction is complete, for re-use.

Wright's macrocycle template, he says might be the ship itself in the catalytic

bottle.

P.A. Wright et al., Angew. Chem. Int. Ed. Engl., 1997, 36, 81.

V. Patinec, P. A. Wright, P. Lightfoot, R. A. Aitken and P. A. Cox, Dalton

Trans., 1999, 3909.

R. E. Morris and P. A. Wright, Chem Ind, 1998, 256.

P.A.Wright, Chem. Mater., 1999, 11, 2456.

Back to the index

Nothing lasts forever

If left at room temperature dehydrated carbonic acid (the

stuff that makes rain and blood acidic) will last for 0.18 million years,

according to Austrian and British theoretical chemists, which is quite a long

time for a supposedly reactive and unstable chemical.

Klaus Liedl and his colleagues at Innsbruck

University working with a team at Queen Mary and Westfield College London

believe the secret lies in the low rate at which the molecule of carbonic acid

in a sample decays to release water and carbon dioxide. But, once the first

drops of water are formed and bubbles of CO2 released the whole process quickly

accelerates leading to the breakdown of the whole sample.

The hydration of carbon dioxide is a

fundamental biochemical reaction - being at the heart of the outgoing stage of

respiration and other key metabolic processes. Carbonic acid the partner of CO2

in these processes also finds itself in a critical position in inorganic

reaction schemes in nature and the laboratory. Despite its prominence, however,

synthesising the compound has been difficult and even spotting the raw H2CO3 as

a reaction intermediate has been hampered by its rapid decay. There was even the

notion that the pure compound didn't exist.

The team applied various theoretical modelling

techniques to carbonic acid's decomposition kinetics to try and discover why it

had remained such an elusive character. Their startling results demonstrate that

pure carbonic acid in the gas phase is in fact a very stable compound with a

half-life of 180,000 years! Their calculations however show that should

just a single molecule of water become embroiled with H2CO3, for instance, if

one molecule of acid breaks down in a sample, then a self-catalysing process

takes over the leads to the ultimate demise of the sample. One potential application of the research is in

the study of interstellar chemistry. If, as turns out to be the case, pure

carbonic acid is quite stable, then it may be involved in all kinds of cosmic

chemistry perhaps even in the formation of fullerenes and their ilk in the

interstellar dust.

Angew. Chem. (Engl. Edn.), 2000, 39, 891

Now you see it..

Back to

the index

Acetylene direct

A room temperature method for converting natural gas into the

more useful organic acetylene has been developed by Japanese chemists. The

technique uses an electric discharge rather than the 1273K pyrolysis

temperatures normally required for such a direct conversion making it a simpler

and cleaner process for utilising non-oil-derived chemical feedstocks.

Shigeru Kado and his colleagues the University

of Tokyo point out that methane is usually so stable that the only way to

directly convert it into higher hydrocarbons is to use a combination of high

pressure, high temperature or a suitable catalyst in a plasma discharge. With an

NaY zeolite catalyst high yields of C2 hydrocarbon can be produced but while

simply heating to the pyrolysis temperature is effective at conversion the blast

usually decomposes much of the product down to carbon.

The Japanese team wanted to avoid the use of

catalysts and high temperatures. ' We are using a pulse discharge lasting less

than 1 microsecond which means only electrons are accelerated and other species

remain in a non-equilibrium state, keeping the reaction at room temperature in

the gas phase, and the products are not decomposed,' explains Kado.

They built a flow reactor into which methane

could be pumped at atmospheric or higher pressure for greater product throughput

and ambient temperature. At each end of the flow chamber they placed a steel

electrode. With pure methane being fed in they pulsed the gas at up to 60 Watts

and obtained greater than 90% conversion to acetylene in the absence of

catalyst. There was little ethylene or ethane by-product. While conversion to

yet higher hydrocarbons such as prop-1-yne and buta-1,3-diene was less than 1%.

However, there was some soot deposition on the

electrodes and the inside of the reaction chamber, which Kado says ultimately

blocks the reaction. A 5:1:4 mix of methane:oxygen:argon helped reduce soot

formation.

They found that with this gas feed there was

not much change to the overall reaction products with the proportions of

side-products remaining fairly constant although there was of course, the

additional side products of carbon monoxide and dioxide. But, the reaction of

the soot with the oxygen under discharge from which these side-products

originate actually stabilises the discharge itself so boding well for a longer

running reaction.

The team points out that they can avoid carbon

monoxide as a by-product by using methane mixed with hydrogen gas at 1:4. This

also helps stabilise the discharge and up to a limit achieves similar conversion

selectivity.

Kado says the team hopes to combine the

discharge approach with catalysis to develop the method for activation of

methane to methanol, for instance.

Chemical Communications, (1999, 2485).

Porous minerals, such as

zeolites, existed in nature for

millions of years before chemists spotted their potential. They have now used

them to sieve out compounds one from another, catalyse reactions, single out

other molecules in sensors and make soap powder work more effectively by mopping

up dissolved metal ions. There are, however, a limited number of these

off-the-shelf minerals in nature so chemists have spent the last few years

looking for ways to tailor their own versions for specific separating, catalytic

and sensors.

Porous minerals, such as

zeolites, existed in nature for

millions of years before chemists spotted their potential. They have now used

them to sieve out compounds one from another, catalyse reactions, single out

other molecules in sensors and make soap powder work more effectively by mopping

up dissolved metal ions. There are, however, a limited number of these

off-the-shelf minerals in nature so chemists have spent the last few years

looking for ways to tailor their own versions for specific separating, catalytic

and sensors.