A Sciencebase reader emailed to ask where they could find more information on Isolagen and its research into a system for eradicating wrinkles and facial scars. So here’s what we found:

Isolagen specializes in the development and commercialization of autologous cellular therapies for tissue regeneration and on May 23rd unveiled a design for an automated system to propagate and harvest cells more efficiently and cost effectively than other cell harvesting systems currently available. The ACE system could be used by cell and tissue companies worldwide and a successfully implemented ACE system would dramatically improve the time and cost of propagating and harvesting cells.

“We’ve invested significant resources to make the cell propagation process scalable, consistent and cost-efficient,” said Isolagen’s Chairman and interim CEO Frank DeLape. “The Automated Cellular Expansion (ACE) System is a simple solution that should enable us to introduce the Isolagen Process on a global scale, and will allow us to pursue licensing opportunities with organizations engaged in cell propagation and harvesting.”

Experts in the cell biology field acknowledge the potential significance of the ACE technology. “This system could significantly reduce the time and resources needed by any research or commercial lab that grows cells, while ensuring the consistency of cell growth and reducing the potential for culture contamination,” said Dr. Mark P. Lewis, Director of Research Operations and Senior Lecturer at Eastman Dental Institute of University College London.

Isolagen is best known for its patented Isolagen Process in which a patient’s own cells are used to correct and reduce the normal effects of aging and replenish deficiencies caused by the loss of fibroblast cells as a person ages. An aesthetic dermal application is currently available in the UK and is in Phase III pivotal clinical trials in the US. A Biologics License Application is expected to be filed with the FDA in late 2005. In addition to dermal indications, Isolagen is researching the use of autologous cellular therapies to treat gum recession, acne scarring and wound healing among other indications.

Growing Cells: Effective But Not Efficient

Cell propagation in Isolagen’s London and Houston laboratories is effective, but labor-intensive and time consuming. The Isolagen Process begins when a physician takes a small tissue sample from which millions of fibroblast cells are extracted and allowed to multiply in the laboratory. The regenerated fibroblast cells are then injected into the patient’s wrinkles when the cells reach a target quantity.

In preparing for its global market launch, Isolagen devoted significant resources to create a system that would make cell propagation and harvesting scalable and more efficient. Several years ago, a team of Isolagen scientists and engineers set out to design an automated cellular expansion (ACE) system that would substantially improve capacity and operating margins.

“The original business plan for Isolagen called for a single lab in every country, so the concept of scalability was not a priority,” said Mr. DeLape. “Our science has advanced to the point that we now envision a single laboratory serving multiple continents utilizing an efficient method of cell propagation and harvesting on a commercial scale.” Mr. DeLape noted the company recently announced the acquisition of a facility in Neuchatel, Switzerland intended to service Europe, Asia and Africa, and the purchase of a lab in Exton, PA to service the Central and South America and the United States once FDA approval is obtained.

ACE Advances Cell Propagation

The ACE unit consists of two separate and distinct parts. The first is a permanent unit, housing circuitry, pumps and a thermo-electric heater. The second part is the disposable unit, which contains a “cell tower,” media bags, cell separator and a sterile tubing for media flow. Cells are placed within the cell tower, which is designed to accommodate the growth of the cells, eliminating the time-consuming transfer of growing cells into new flasks. Every step, from feeding the cells to the harvesting of the injection syringes, will be executed in a sterile, closed-loop system.

The design eliminates nearly all human intervention, dramatically reducing the chance of contamination and the technical labor and monitoring associated with the process. And, the footprint of the Isolagen ACE unit as designed is small, allowing for modular stacking and maximum space efficiency.

“We are confident that we can maintain the quality and consistency of cell production, realize substantial savings and gain tremendous efficiencies through the use of the ACE System,” said Mr. DeLape. “Although ACE was developed to provide large-scale improvements in capacity and operating margins for the production of the Isolagen Process, we believe that ACE represents substantial improvements in cell propagation and harvesting for many other applications. Following the anticipated successful implementation of ACE for the Isolagen Process, we intend to seek licensing opportunities with other cell-based companies thereby creating a new revenue stream for our shareholders.”

The Isolagen ACE system was designed in collaboration with Fairway Medical Technologies and International Biophysics Corporation, leaders in medical device and equipment technology.

Logistical Advances Inherent with ACE

This fully automated, sterile closed-loop system is designed to offer enhanced benefits for other aspects of the Isolagen Process. The ACE design secures and records the identification of each patient’s cells through every step of the process — from biopsy to injection — creating a clear electronic chain of custody. Cells will be contained in a cell tower, which is designed to accommodate the expansion and growth of the cells and monitor cell growth and cell count to effectively predict when the target number of cells will be reached. In addition, Isolagen intends to utilize cryogenic preservation and freezing technology to allow maximum flexibility in scheduling treatments.

Next Steps

Isolagen intends to introduce ACE technology in the UK and its new Swiss facility during 2006.

About Isolagen

Isolagen specializes in the development and commercialization of autologous cellular therapies for soft and hard tissue regeneration. The company’s product candidates are based on its proprietary Isolagen Process and are directed toward dermatology — facial rejuvenation, gingival disease — gum disease, vocal cord lesions, and wound treatment. Based on the accumulated experience of the company through its pre-clinical studies, clinical trials and treatment of patients in the United Kingdom, the company believes that the Isolagen Process utilizing a patient’s own cells creates a safe and effective therapy for facial rejuvenation. Pre-clinical and clinical studies for future autologous therapies are ongoing. Autologous cellular therapy is the process whereby a patient’s own cells are extracted, allowed to multiply and then injected into the patient. Isogalen’s product candidates are designed to be minimally invasive and nonsurgical.

For additional information, please visit: http://www.isolagen.com .

A mixture of horseradish and peroxide can (apparently) dampen swine farm odours.

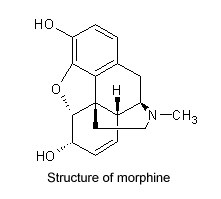

A mixture of horseradish and peroxide can (apparently) dampen swine farm odours. Since 1805, morphine and its derivatives have become the most widely used treatment for severe pain. Now more than 230 tons of morphine is used each year for medical purposes including pain relief for patients with chronic pain or advanced medical illness and post-operative analgesia. By the way, if you’re looking for a chemical structure for opium, you’re out of luck. Opium is not a single compound but an extract of the immature seeds of the opium poppy, Papaver somniferum. This extract contains up to 10% morphine, the opiate alkaloid, which is processed to produce diamorphine, better known as heroin. The resin also includes codeine and non-narcotic alkaloids, such as papaverine and noscapine.

Since 1805, morphine and its derivatives have become the most widely used treatment for severe pain. Now more than 230 tons of morphine is used each year for medical purposes including pain relief for patients with chronic pain or advanced medical illness and post-operative analgesia. By the way, if you’re looking for a chemical structure for opium, you’re out of luck. Opium is not a single compound but an extract of the immature seeds of the opium poppy, Papaver somniferum. This extract contains up to 10% morphine, the opiate alkaloid, which is processed to produce diamorphine, better known as heroin. The resin also includes codeine and non-narcotic alkaloids, such as papaverine and noscapine. Serturner found that opium with the alkaloid removed had no effect on animals, but the alkaloid itself had ten times the power of processed opium. He named that substance morphine, after Morpheus, the Greek god of dreams, for its tendency to cause sleep. He spent several years experimenting with morphine, often on himself, learning its therapeutic effects as well as its considerable dangers. Although his work was initially ignored, he recognized its significance. “I flatter myself,” he wrote in 1816, that “my observations have explained to a considerable extent the constitution of opium, and that I have enriched chemistry with a new acid (meconic) and with a new alkaline base (morphium), a remarkable substance.”

Serturner found that opium with the alkaloid removed had no effect on animals, but the alkaloid itself had ten times the power of processed opium. He named that substance morphine, after Morpheus, the Greek god of dreams, for its tendency to cause sleep. He spent several years experimenting with morphine, often on himself, learning its therapeutic effects as well as its considerable dangers. Although his work was initially ignored, he recognized its significance. “I flatter myself,” he wrote in 1816, that “my observations have explained to a considerable extent the constitution of opium, and that I have enriched chemistry with a new acid (meconic) and with a new alkaline base (morphium), a remarkable substance.”